Modern power generation and industrial steam production rely heavily on efficient boiler operations. Within a boiler island, numerous interconnected components work together to convert fuel into thermal energy. Among these components, the ash and slag removal system of boiler island plays a critical role in maintaining operational efficiency, environmental compliance, and long-term reliability. Without effective ash and slag handling, even the most advanced boiler technology can suffer from performance degradation, unplanned shutdowns, and increased maintenance costs.

This article explores how the ash and slag removal system of boiler island enhances boiler efficiency, supports sustainability goals, and ensures smooth plant operations.

Understanding the Boiler Island Concept

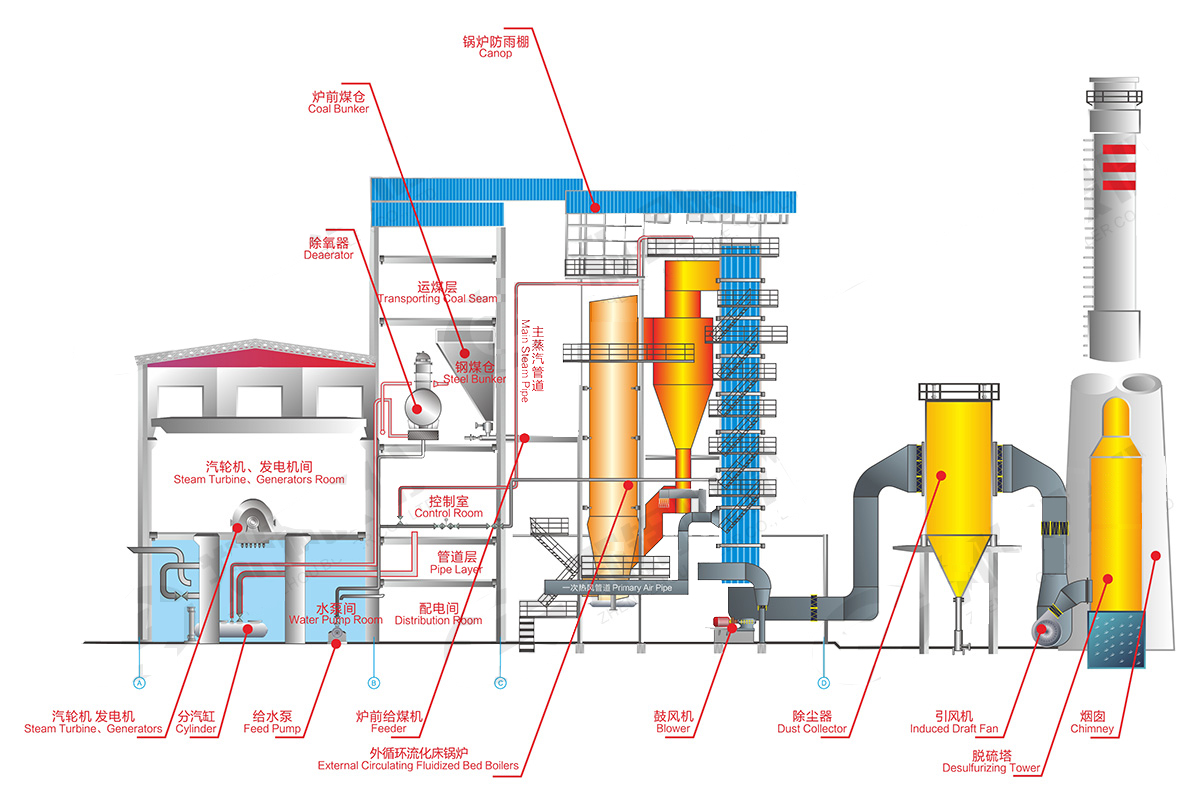

A boiler island typically refers to the integrated system that includes the boiler, combustion equipment, heat recovery systems, and supporting subsystems such as fuel handling, air supply, flue gas treatment, and ash handling. In coal-fired and biomass-fired power plants, combustion produces significant amounts of ash and slag as byproducts.

Ash can be categorized into:

- Bottom ash, which collects at the base of the furnace

- Fly ash, which is carried by flue gases

- Slag, which forms when ash melts and solidifies in high-temperature zones

Efficient handling of these byproducts is essential. This is where the ash and slag removal system of boiler island becomes indispensable.

The Importance of Ash and Slag Management

During combustion, mineral impurities in fuel do not burn. Instead, they form ash and slag deposits. If these materials are not removed promptly and effectively, they can cause:

- Reduced heat transfer efficiency

- Blocked gas passages

- Corrosion and erosion of boiler tubes

- Increased pressure drop

- Higher fuel consumption

- Unexpected outages

A well-designed ash and slag removal system of boiler island ensures that these residues are continuously extracted, preventing accumulation and protecting critical boiler components.

Components of an Ash and Slag Removal System

The ash and slag removal system of boiler island consists of several integrated subsystems, each designed for a specific function.

Bottom Ash Handling System

Bottom ash accumulates at the furnace bottom. Removal methods include:

- Wet bottom ash systems with water-filled hoppers

- Dry bottom ash systems with mechanical conveyors

- Hydraulic sluicing systems

These systems cool, collect, and transport bottom ash to storage or disposal units without interrupting boiler operations.

Fly Ash Handling System

Fly ash is captured from flue gases using electrostatic precipitators or bag filters. Once collected, it is transferred through pneumatic conveying systems to silos for storage.

An efficient ash and slag removal system of boiler island ensures minimal ash escape, protecting air quality and meeting environmental regulations.

Slag Removal Mechanisms

Slag forms in high-temperature zones and can adhere to furnace walls. Slag removal equipment, such as clinker grinders and slag crushers, breaks down large slag masses for easier transport and disposal.

Proper slag handling prevents furnace damage and ensures stable combustion conditions.

Enhancing Boiler Efficiency Through Effective Removal

The ash and slag removal system of boiler island directly impacts boiler performance in several ways.

Maintaining Optimal Heat Transfer

Ash deposits on heat exchange surfaces act as insulation, reducing heat transfer efficiency. This forces the boiler to consume more fuel to maintain the same steam output.

By continuously removing ash and slag, the system preserves clean heat transfer surfaces, improving thermal efficiency and lowering fuel costs.

Reducing Maintenance Downtime

Accumulated ash and slag can cause mechanical wear, corrosion, and tube failures. Scheduled cleaning and robust removal systems reduce emergency shutdowns and maintenance frequency.

A reliable ash and slag removal system of boiler island minimizes operational disruptions and extends equipment lifespan.

Supporting Stable Combustion

Excessive slag formation can alter furnace geometry and airflow patterns. This leads to unstable combustion, higher emissions, and uneven temperature distribution.

Efficient slag removal ensures consistent combustion conditions, contributing to steady steam generation and improved energy output.

Environmental Compliance and Sustainability

Environmental regulations require strict control over particulate emissions and waste disposal. The ash and slag removal system of boiler island plays a vital role in meeting these standards.

Controlling Airborne Particulates

Fly ash capture systems prevent particulate matter from being released into the atmosphere. Advanced pneumatic conveying and storage solutions ensure safe handling and minimal leakage.

Facilitating Ash Recycling

Fly ash can be reused in cement production, construction materials, and road base applications. A well-designed ash and slag removal system of boiler island enables proper ash classification, storage, and transport for beneficial reuse.

This supports circular economy initiatives and reduces landfill dependency.

Preventing Water Contamination

Wet ash handling systems must manage wastewater effectively to prevent contamination. Modern systems incorporate dewatering technologies and closed-loop water recycling to reduce environmental impact.

Technological Advancements in Ash and Slag Removal

Recent innovations have improved the efficiency and reliability of ash handling systems.

Dry Ash Handling Systems

Dry systems reduce water consumption and eliminate the need for ash ponds. They also improve ash quality for reuse in industrial applications.

Automated Monitoring and Control

Advanced sensors and control systems monitor ash levels, conveyor performance, and system pressure. Automated controls optimize operation and detect potential failures before they escalate.

An intelligent ash and slag removal system of boiler island enhances plant safety and operational transparency.

Energy-Efficient Conveying Solutions

Modern pneumatic and mechanical conveying systems are designed to minimize power consumption while maximizing reliability.

Energy-efficient ash transport contributes to overall plant efficiency gains.

Economic Benefits of Optimized Ash Handling

Investing in a high-performance ash and slag removal system of boiler island delivers measurable financial advantages.

- Lower fuel consumption due to improved heat transfer

- Reduced maintenance and repair costs

- Fewer forced outages

- Revenue from fly ash sales

- Compliance with environmental standards, avoiding penalties

In competitive energy markets, operational efficiency directly impacts profitability. Effective ash and slag management supports both short-term performance and long-term asset value.

Challenges and Best Practices

Despite its importance, designing and operating the ash and slag removal system of boiler island presents challenges.

Handling Abrasive Materials

Ash and slag are highly abrasive, requiring durable materials and wear-resistant components.

Ensuring System Reliability

Continuous operation demands robust design, redundancy, and preventive maintenance.

Integrating with Overall Plant Systems

Ash handling must align with combustion control, flue gas treatment, and waste management systems for seamless operation.

Best practices include regular inspection, predictive maintenance, system upgrades, and operator training to ensure consistent performance.

The Strategic Role of Ash and Slag Removal in Boiler Islands

In modern power plants, efficiency is not determined solely by combustion technology. Supporting systems are equally critical. The ash and slag removal system of boiler island is a strategic component that protects equipment, enhances heat transfer, supports environmental compliance, and contributes to economic performance.

As industries strive for higher efficiency, lower emissions, and sustainable operations, optimized ash and slag handling systems will continue to play a pivotal role. By investing in advanced technologies and best operational practices, plant operators can significantly enhance boiler island performance while ensuring reliable and environmentally responsible energy production.